PRODUCTS

INNOTRO Co., LTD. is building the power to lead with cutting-edge technology.

INNOTRO Co., LTD. is building the power to lead with cutting-edge technology.

INNOTRO Co., LTD. is comprised of the CP Division, LF Division, and RO Division.

The LF Division is engaged in etching of lead frames and high-tech components.

*Production capacity: 2,800,000 frames/month

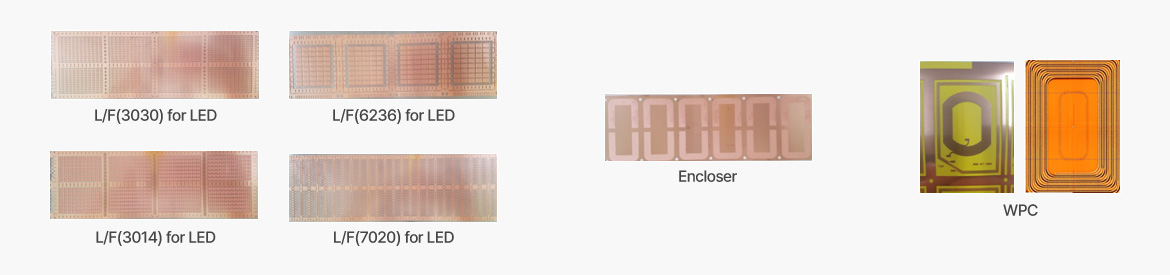

Camera Module Device Wireless Power Charger IC-PKG Leadframe LED Leadframe RIS Antenna

The LF Division performs etching processes for manufacturing components such as LEDs, semiconductor lead frames, and heat shields.

Precise implementation of customer-required patterns constitutes our core competitive edge.

The company’s technical capabilities are at the ±5um level for Half Etching depth tolerance, and for Fine Pattern, it is at the level of 5mil 130pitch & 6min 150pitch.

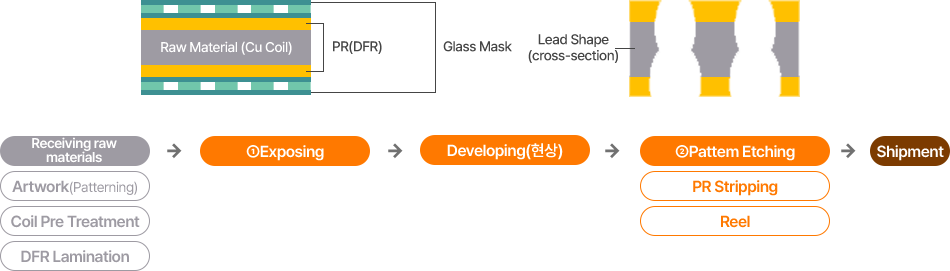

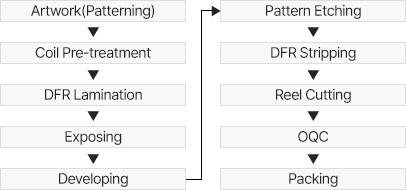

Artwork (Patterning)

Realize complex, diverse patterns requested by customers in precision

Half Etching

Implement semi-etching by chemical treatment on copper plate for heat shielding plates

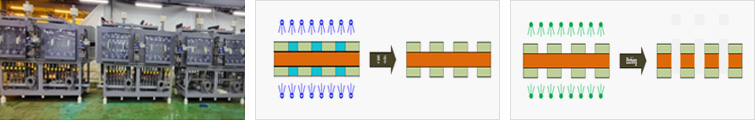

R2R

Roll to Roll method

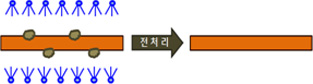

| Pre-treatment | Removing oil and impurities |  |

※ It removes impurities through alkaline agents and forms inorganic impurities and surface micro-roughness through strong acids(DFR adhesion increases). |

|---|---|---|---|

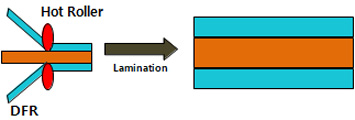

| Lamination | Dry film deposition |  |

※ It deposits DFR for exposure on the surface of the raw material using a high-temperature hot roller, and then proceeds with recoiling. |

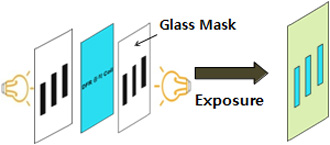

| Exposure | Dividing into hardened and uncured parts using a glass mask and light |  |

※ It removes the DFR from the uncured area (part not exposed to light) by using an alkaline chemical to expose the coil. |

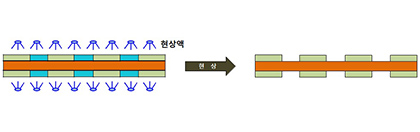

| Developing | Exposing coil through removal of DFR in uncured area |  |

※ It removes the DFR from the uncured area (part not exposed to light) by using an alkaline chemical to expose the coil. |

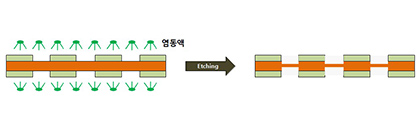

| Etching | Etching exposed coil areas |  |

※ It is etchedto the desired thickness by controlling the pressure on the exposed coil areas using an electrophoresis solution. |

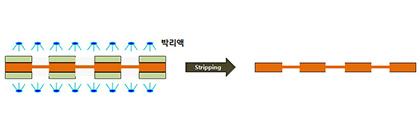

| Stripping | Removing residual DFR so that only coil remains |  |

※ Residual DFR (hardened zone between exposures) s removed using strong alkaline chemicals, ultimately leaving only the coils. |

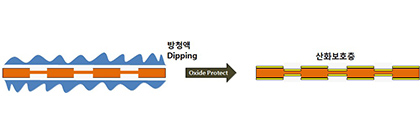

| Final post-treatment |

Removing oxidation protection layer and chemicals |  |

※ It prevents product oxidation through rust prevention chemicals, and it removes chemicals by forming a protective layer and washing with water. |

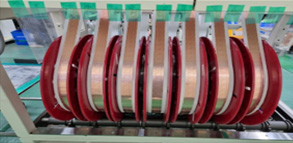

| Recoiler | Winding the completed product onto the bobbin |  |

※ Finished products are wound onto bobbins, transported to the warehouse, and then packaging is carried out. |